The Fiberglass Difference

Fiberglass tanks are watertight for 100% containment of hydrocarbons and can be double-walled, as well as electronically monitored. We offer a full family of accessories including, piping, coalescers, risers, and traffic-rated covers to meet system performance.

Fiberglass tanks are corrosion-resistant for grease applications, unlike concrete tanks that have a limited life span due to internal corrosion because of high temp and pH conditions in grease interceptors. Fiberglass tanks are built with thermostat resins that can be specifically formulated to offset these unique corrosive conditions. These tank properties allow for a tank installation that will far exceed the life span of other steel or concrete products.

Durability

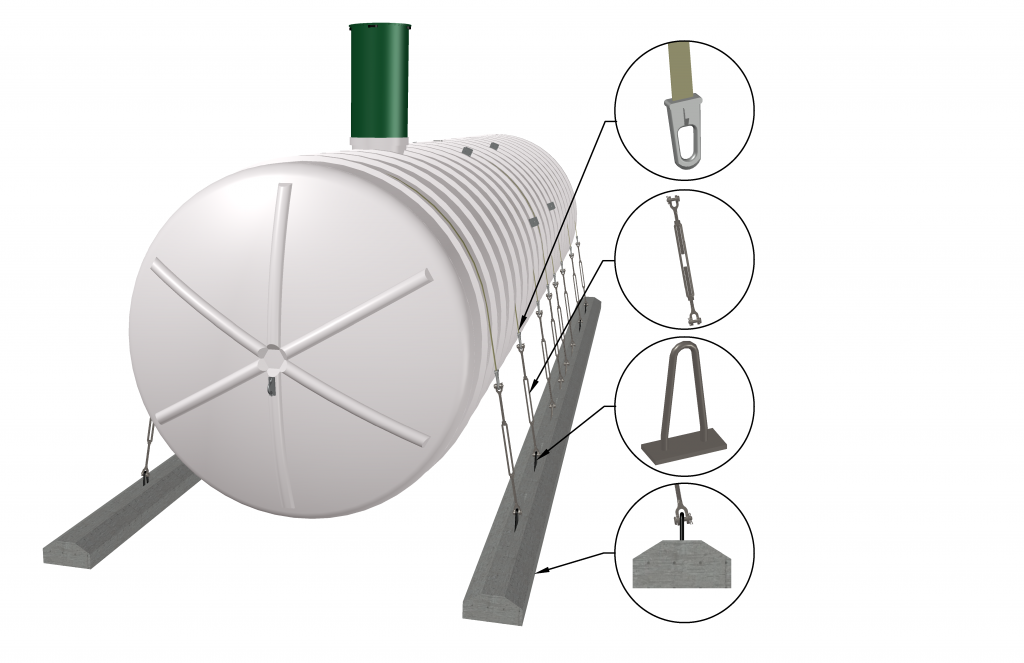

Our tanks are built to withstand upthrust from ground water, offset sidewall buckling from soil loads, and can withstand H-20 traffic loads. By nature, fiberglass tanks are flexible and utilize geometry and sandwich laminate construction techniques to provide proven designs for underground applications. These designs are mathematically calculated and manufactured with quantitative industry safety factors. As an example, our standard tanks are designed for 7’ of bury, fully flooded to grade, in an empty condition. We also builds underground storage tanks for deep bury applications, exceeding 7’ of cover.

Our lower-volume interceptors keep oils, grease, sand, and grit out of the municipal sewer collection system, reducing maintenance on sewer lines, blockage, and settlement in the pipes.

Our higher-volume separators reduce oil from runoff pollutants, and can be designed to UL 2215 standards and for quantitative removal rates, based on inlet strength characteristics, and discharge limits.

Copywrite Nwaj.Digital 2023