Advance Products & Systems, LLC, founded in 1978, is a leading manufacturer and distributor of water & wastewater, oil & gas, industrial & mechanical, and chemical pipeline products. Our products are manufactured for these industries to prevent and protect against unwanted corrosion. APS also offers quality safety products manufactured to meet customers’ needs to protect personnel, equipment, and the environment.

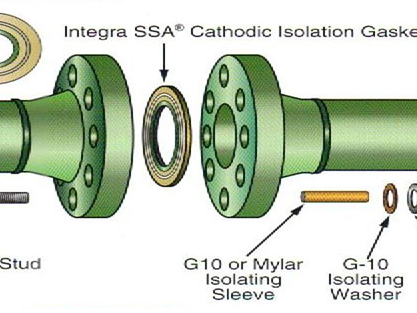

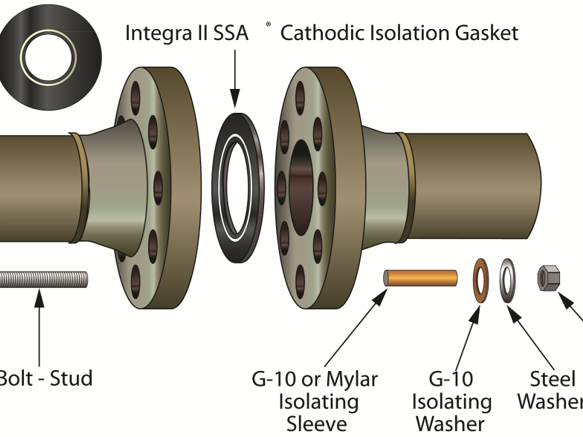

Gasket Type: E or F Gasket Material: Glass Reinforced Epoxy (G-10) Bonded to 316 Stainless Steel Core Seal: Spring Energized Teflon Seal Gasket Thickness: 0.250″ Sleeves: G-10 or Mylar Washers (Double): G-10, Carbon Steel Zinc Plated, Hardened Steel, or Teflon Coated

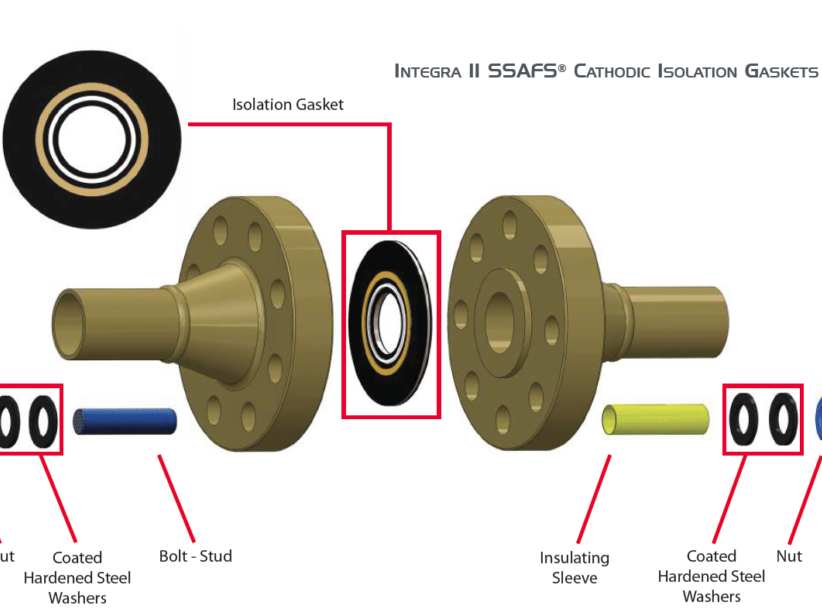

Gasket Type: E or F Gasket Material: Glass Reinforced Epoxy (G-10) Bonded to 316 Stainless Steel Core Seal: Spring Energized Teflon Seal (Primary) and Fire Safe Phyllosilicate Seal (Secondary) Gasket Thickness: 0.274″ Sleeves: G-10 or Mylar Washers (Double): Coated Hardened Steel, G-10, or Carbon Steel Zinc Plated

Kleerband Flange Protector Radolid Nutcap Kleergel Grease Cartridge Stainless Steel Flange Protector

Casing Spacer End Seal Innerlynx® Modular Seal Bore Spacer

VERSATILITY – With a wide variety of sizes available, UBolt-Cote can be applied to all makes and sizes of U-Bolts. PROTECTION – A rugged and durable covering eliminates metal to metal contact. RELIABILITY – UBolt-Cote provides high abrasive and corrosive resistance through a continuous sheath which eliminates fraying and unraveling. UBolt-Cote is virtually unaffected by heat, ultraviolet rays, vibration, electrolysis, sandblasting or any other rigors conducive to an industrial and marine environment. EASE OF INSTALLATION – The UBolt-Cote size has been considered to accommodate the coating thickness assuring a secure fit over the pipe.

- 1

- 2

Copywrite Nwaj.Digital 2023