Advance Products & Systems Casing Spacer

- Easy and efficient to install requiring no grease and no special tools

- Installation by one person

- Slides into place with ease

- Coefficient of friction = .1

- Requires no backfill

- Decades of proven reliability Insulating and long-term corrosion protection

- Anti-corkscrewing Casing Spacer with Rollers now available

Advance Products & Systems End Seal

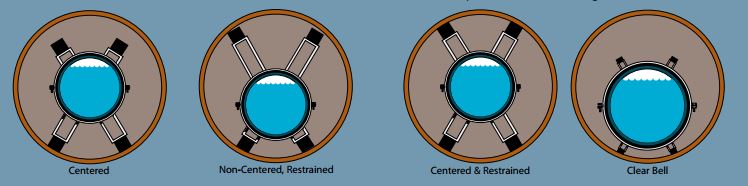

Advance Products & Systems End Seals outperform the costly and labor intensive brick and mortar method of sealing casing ends. While soil stress and pipe movement cause mortar to crack, the APS products move with the pipe insuring the integrity of the seal. And, unlike link-type sealing blocks that are limited to carrier/casing differential and can only be used on a concentric profile, the APS seals are totally flexible. APS offers four types of end seals which can accommodate any combination of pipe sizes.

Advance Products & Systems Innerlynx® Modular Seal

- Innerlynx® offer 21 different sizes for all pipe diameters ranging from 1/2” – 144”.

- Innerlynx® are made from synthetic rubbers with industrial strength UV and ozone resistant plastic or all metal plates.

- Innerlynx® help absorb vibrations, shocks, and sound waves and act as a sound dampener.

- Innerlynx® come in 5 models; EPDM Black, Nitrile Green, Silicone Grey, EPDM Blue & Silicone Red.

- Innerlynx® form a hydrostatic seal up to 40 psig and up to 92.28 feet of head pressure.

- Innerlynx® can be easily reinstalled many times over the life of the installation.

- Innerlynx® are manufactured and assembled in the U.S.A.

- Innerlynx® electrically isolate the inner carrier pipe from the penetrated structure.

- Innerlynx® can be installed easily and quickly by one worker with no special tools.

Advance Products & Systems Bore Spacer

APS Bore Spacers are designed to support and cradle conduit for ease of installation, allowing optimal free flow of grout, thereby eliminating voids. Bore Spacers also maintain accurate conduit position and alignment that will result in a reduction of installation time, isolation, boosting efficiency and ensuring that the installation is performed correctly.

Available Features:

• Solid high strength HDPE or Polypropylene body

• Multiple conduit sizes and designs

• Accommodates any type conduit or casing pipe

• Conduit to conduit separation to specification

• Strategically located holes for grout injection hose

• Conduit bank flotation prevention

• Holes for stabilization cable, scalloped perimeter

• Conduit bank weight is balanced on CL

• HDPE or Polypropylene wheels with steel axle

• HD strapping or Nylon 275 lb tie straps

• 8” to 96” diameter casing

Bore Spacer Specifications:

Dielectric Strength (ASTM D-149): 450-500 Volts/Mil

Flexural Strength (ASTM D-790): 4600 psi

Compressive Strength (ASTM D-695): 4600 psi

Tensile Strength (ASTM D-638, D-651): 4600 psi

Water Absorption (ASTM D-570): 0

Impact Strength (ASTM D-256): 3.0 ft lb/in of notch

Material: HDPE

Max Continuous Operating Temp (1/2” & 3/4” HDPE): 180 °F (82 °C)

Copywrite Nwaj.Digital 2023